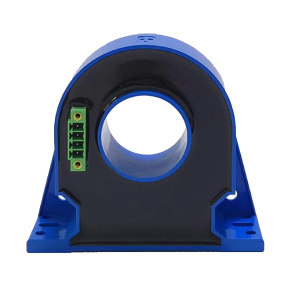

Introduction of Hangzhi HIT Current sensor

Hangzhi HIT series current sensor is a product based on the principle of fluxgate, which is specially designed to replace the Hall current sensor in large quantities. Compared with closed-loop Hall current sensors, HIT series sensors perform better in performance. Its accuracy can reach 0.05%, much higher than the 0.2% of the closed-loop Hall effect current sensor. In addition, the bandwidth of the HIT series sensor can reach 100kHz, which is 2 times higher than that of the closed-loop Hall current sensor. At the same time, the HIT series sensor realizes a miniaturized design, and the interface and volume are the same as the Hall current sensor, which is convenient for direct replacement. The product models of this series are: HIT50, HIT100, HIT200, HIT300, HIT500, HIT600, which can measure DC, AC and pulse current from 50A to 600A.

r&d Background for VACUUM COATING MACHINE

As a key equipment, the vacuum coating machine is used for thin film coating in a vacuum environment. It has a wide range of applications in optical coating, metal coating and other fields. Accurate monitoring and control of the current is key to achieving high-quality thin films. Traditional current sensors have problems such as large temperature drift and low precision in a vacuum environment, which restrict the performance and process stability of vacuum coating machines.

Pain points of using Tradition method

The application of the current sensor on the vacuum coating machine is mainly used to monitor and control the current. In the vacuum coating machine, due to the large temperature change in the high vacuum environment, the sensor may be affected by the temperature, resulting in a deviation in the output current value. If the temperature drift of the current sensor is large, the current control of the system will be inaccurate, thereby affecting the deposition rate and thickness uniformity of the film. If the accuracy of the current sensor is low, that is, there is a large deviation between the output current value and the real value, the system will not be able to accurately control the deposition rate and film thickness. Especially for some applications that require high film quality, such as optical coating, a current sensor with low accuracy may cause the optical properties of the film to be unstable or not meet the specification requirements. In the traditional way, the Hall current sensor is commonly used to detect the current value. However, the traditional Hall current sensor has problems such as large temperature difference and insufficient precision, which restrict the performance and stability of the vacuum coating machine.

Hangzhi HIT Hall effect substitute current sensor solution

In order to solve these problems, Hangzhi proposed a current sensor solution based on the principle of fluxgate technology. The characteristics of high precision and low zero drift fully meet the application requirements of vacuum coating machines.

By accurately measuring and controlling the current, the high-precision current sensor enables more accurate deposition rate and thickness control, thereby improving the uniformity and quality stability of the film. In applications such as optical coatings that require high film quality, high-precision current sensors can help achieve higher optical performance and surface flatness.

Accurate current measurement and control helps to optimize process parameters and improve the production efficiency of vacuum coating machines. By fine-tuning the current, faster deposition rates or less energy consumption can be achieved, increasing equipment utilization and throughput.

The stability of the high-precision current sensor is better, which can reduce the drift and fluctuation of current measurement and improve the stability of the process. Stable current control helps reduce film fluctuation and non-uniformity, improving product consistency and repeatability.

The application of Hangzhi current sensor in vacuum coating machine can effectively solve the pain points of traditional solutions, improve film quality and process stability, improve production efficiency and product consistency, and bring greater advantages and application potential to vacuum coating machine.

Specifications of Hangzhi HIT Current Transducers

High precision: 0.05%

Measurement Range: 10 to 1000A,

Full Scale Range: 1%-100% accuracy of a single product is consistent

Small temperature drift: good consistency, temperature influence, 0.1PPM/degree

Linearity: up to 50ppm

Wide Bandwidth: (up to 100kHz @±3 dB)

Response time: 1μs

Operating temperature range: -40..+85 °C

Stability (0.2 ppm/month)

AC and DC universal: can measure AC, DC, pulse current

Intelligent: load start overload protection, self-recovery

About Hangzhi

Shenzhen Hangzhi Precision Electronics Co., Ltd. is a technology-leading enterprise dedicated to the R&D, production, sales and solution customization of high-precision current sensors, voltage sensors, and high-precision electrical measuring instruments. We strive to build a well-known brand of precision current sensors and precision electrical measuring instruments in the DC field, and strive to develop into an international leading company in precision electronics in the field of DC systems.