About aIT high precision current sensor

Hangzhi precision high-precision current sensor is a multi-point zero-flux technology system applied to the existing high-precision DC sensor technology. The combination of excitation flux closed-loop control technology, self-excited fluxgate technology and multi-closed-loop control technology realizes the excitation The zero-flux closed-loop control of magnetic flux, DC magnetic flux, and AC magnetic flux realizes the detection of high-frequency ripple by building a high-frequency ripple induction channel, so that the sensor has a relatively high gain and measurement within the full bandwidth range A current measurement and feedback component with high precision. Usually used in power electronic equipment, electrical control systems and other fields. This article will introduce the application of high-precision current sensors in battery test equipment.

r&d Background for wind turbine test bench

Wind power generation is a renewable energy power generation method, which uses wind power to drive wind turbines to rotate and generate electricity. Wind power has become one of the important energy industries worldwide, and its renewable, clean and low-carbon characteristics make it of great significance in reducing dependence on fossil fuels and reducing greenhouse gas emissions.

The wind turbine test bench is the equipment used to evaluate and test the performance of wind turbines. It can simulate the wind environment under different wind speeds and climate conditions, and measure and analyze the output of wind turbines. The test bench usually includes components such as fans, power systems, data acquisition and monitoring systems. With the increasing power of wind turbines and the further development of the wind power industry, wind turbine test benches are facing some new developments and challenges, including the accurate measurement of large currents at high power. Accurate measurement of current is critical to assess generator performance, efficiency and load characteristics.

Pain points of using Tradition method

However, as the power and performance of wind turbines continue to increase, the traditional current sensor solution can no longer meet the needs of accurate evaluation and monitoring of generator performance, thus limiting the efficiency and reliability of the entire system. In the past, Hall effect sensors or resistive sensors were mainly used for current measurement in wind turbine testing, but these two methods have obvious disadvantages. Hall effect sensors have limited sensitivity and are susceptible to interference from external environmental factors such as temperature and magnetic fields, thus affecting the accuracy of current measurement; while resistive sensors will have power loss, which not only affects the actual power output of the system, but also affects the actual power output of the system. Heat will be generated when the current is passed, causing the temperature to rise, thereby affecting the accuracy and stability of the measurement.

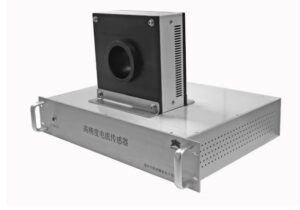

Hangzhi High current sensor solution

In order to solve the problems faced by traditional current sensors, HangZhi proposed a high-precision current sensor solution based on the principle of fluxgate technology. Different from conventional chip sensing methods, this scheme realizes current detection through classical control theory, making the sensor insensitive to external environmental changes, and has almost no temperature drift and zero drift problems. This sensor has small magnetic resistance and high stability of magnetic flux, can provide high-precision current detection, high sensitivity and fast response speed. Its application can reliably support the performance evaluation, monitoring and control needs of wind power generation systems. Usually, high-power wind turbines also generate large currents, so the test bench needs to be equipped with corresponding high-current measurements to ensure accurate measurement and monitoring of system currents. Hangzhi high-precision current sensor can measure up to 8000A current, which can adapt to the high current output generated by high-power wind turbines.

The high-current measurement capability, high-precision measurement, fast response capability, anti-interference capability, safety and high reliability of Hangzhi high-precision current sensor can meet the demand for high-current precision measurement and ensure that the wind turbine test bench has a good impact on the system. Accurate measurement and monitoring of current.

Specifications of Hangzhi High Current Transducers

High precision: 50ppm

Measurement Range: 2000 to 8000A,

Full Scale Range: 1%-100% accuracy of a single product is consistent

Small temperature drift: good consistency, temperature influence, 0.1PPM/degree

Linearity: up to 20ppm

Wide Bandwidth: (up to 800kHz @±3 dB)

Response time: 1μs

Operating temperature range: -40..+85 °C

Stability (0.2 ppm/month)

AC and DC universal: can measure AC, DC, pulse current

Intelligent: load start overload protection, self-recovery

About Hangzhi

Shenzhen Hangzhi Precision Electronics Co., Ltd. is a technology-leading enterprise dedicated to the R&D, production, sales and solution customization of high-precision current sensors, voltage sensors, and high-precision electrical measuring instruments. We strive to build a well-known brand of precision current sensors and precision electrical measuring instruments in the DC field, and strive to develop into an international leading company in precision electronics in the field of DC systems.