About aIT high precision current sensor

Hangzhi precision high-precision current sensor is a multi-point zero-flux technology system applied to the existing high-precision DC sensor technology. The combination of excitation flux closed-loop control technology, self-excited fluxgate technology and multi-closed-loop control technology realizes the excitation. The zero-flux closed-loop control of magnetic flux, DC magnetic flux, and AC magnetic flux realizes the detection of high-frequency ripple by building a high-frequency ripple induction channel, so that the sensor has relatively high gain and measurement in the full bandwidth range. It is usually used in power electronic equipment, electrical control systems and other fields. This article will introduce the application of high-precision current sensors to achieve precise current control in nuclear magnetic resonance equipment.

How does MRI Equipmetn work

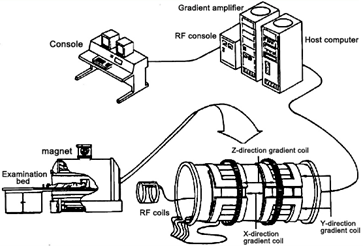

An MRI device is a high-precision medical imaging device that generates images by utilizing the phenomenon of nuclear spin resonance. In the MRI system, the gradient amplifier unit refers to all circuit units related to the gradient magnetic field.

The gradient amplifier is one of the key components for generating gradient magnetic field signals in MRI imaging. It generates magnetic field gradient signals in different directions by controlling the magnitude and direction of the current, thereby realizing the spatial encoding and positioning of MRI images. MRI systems generally require three gradient amplifiers to generate gradient magnetic fields in three different directions to encode and locate signals in three-dimensional space. Therefore, each MRI system generally requires three current control loops, corresponding to gradient amplifiers in the X, Y, and Z directions, respectively.

Each current control loop consists of a current source, a current amplifier and a current sensor. The current source is used to provide a current signal, the current amplifier is used to amplify the current signal and generate a gradient magnetic field through the gradient coil, and the current sensor is used to monitor the current signal to ensure that the generated gradient magnetic field is consistent with the preset gradient magnetic field. The current sensor senses the current signal in the gradient amplifier and transmits it to the control system to monitor and control the current signal. The precision and accuracy of the current sensor directly affect the precision and accuracy of the gradient magnetic field signal generated in the gradient amplifier, thus directly affecting the quality, clarity and resolution of the MRI image.

Pain points of using hall effect current sensor for MRI

In the past, MRI equipment used the Hall effect current sensor for current control, but this sensor has many shortcomings, such as the accuracy cannot meet the requirements, the linearity is not enough, the stability is not good, and it is easily affected by the external environment. These deficiencies will directly affect the quality and clarity of MRI images.

Hangzhi zero fluxgate current sensor solution

Hangzhi developed AIT high-precision current sensor based on the fluxgate principle for high-precision and high-performance applications such as MRI equipment. Compared with traditional Hall effect sensors, the fluxgate high-precision sensor has the following advantages:

High precision: 10ppm

Full range: 1%-100% accuracy of a single product is consistent

Small temperature drift: good consistency, temperature influence, 0.1PPM/degree

Linearity: up to 2ppm

Wide Bandwidth: (up to 800kHz @±3 dB)

Response time: 1μs

Operating temperature range: -40..+85 °C

Stability (0.2 ppm/month)

AC and DC universal: can measure AC, DC, pulse current

Intelligent: load start overload protection, self-recovery

The fluxgate high-precision current sensor can provide more precise current control, making the MRI imaging quality higher; in addition, the high stability of the sensor also ensures the accuracy of imaging. Fluxgate high-precision current sensors can also be used in other fields of high-precision electrical measurement requirements, such as precision power control, power analysis, calibration equipment, and laboratory measurement equipment.

About Hangzhi

Shenzhen Hangzhi Precision Electronics Co., Ltd. is a technology-leading enterprise dedicated to the R&D, production, sales and solution customization of high-precision current sensors, voltage sensors, and high-precision electrical measuring instruments. We strive to build a well-known brand of precision current sensors and precision electrical measuring instruments in the DC field, and strive to develop into an international leading company in precision electronics in the field of DC systems.