How to Calibrate Current Sensors for Maximum Accuracy

Current sensor(also called current transducer) calibration is essential to ensure reliable and accurate readings in a variety of applications. Whether you are using a fluxgate current sensor or a Hall effect current sensor, understanding how to calibrate the current sensor is critical to maintaining system integrity. This article will explore the steps to calibrate a current sensor and explain the importance of calibrating the current sensor for maximum performance.

What is Current Sensor Calibration?

Current sensor calibration is the process of adjusting the sensor output to match the actual current flowing through the circuit. Over time, sensors can lose accuracy due to factors such as temperature changes, wear, or external interference. Calibration of current sensors ensures that the sensor provides accurate readings, which is essential for controlling electrical systems, making precise measurements, and improving system efficiency. Inaccurate readings can lead to errors in data analysis and even cause system failures.

Current Sensor Calibration Steps

In order to effectively calibrate a current sensor, there are several basic steps to follow. The following are general steps that can be adjusted depending on the type of current sensor being used.

- Confirm sensor specifications:

Consult the sensor manual to confirm parameters such as range, output type (such as 4-20mA, 0-5V, digital signal, etc.), accuracy level, supply voltage, etc. - Prepare the test environment:

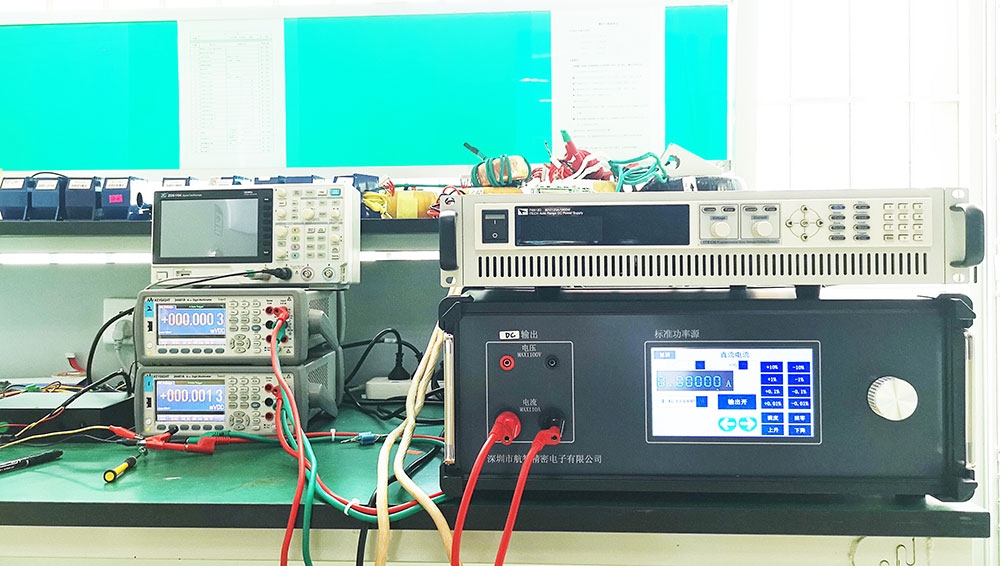

Build a controllable test environment that matches the current sensor to be tested to minimize electrical noise that may affect calibration. - Select a standard current source:

Use a standard current source that has passed the calibration test to output high-precision controllable current. For example, Hangzhi HZ601 series programmable DC standard source. - Select standard measurement equipment:

Use a high-precision multimeter or oscilloscope as a measurement device. The measurement accuracy of the equipment must be higher than the nominal accuracy of the sensor. - Configure an appropriate amount of load resistance or load equipment:

Loads may be required during the test, such as matching loads when the output is a current signal. - Safety measures:

Make sure the circuit is disconnected to avoid high current overload or short circuit. - Calibration test:

After preparation, the current sensor needs to be calibrated at zero point, full scale, linearity verification, temperature drift test, etc. - Record documents

Record detailed calibration data, including: input current, output value, error, environmental conditions, etc.

Generate a calibration report with calibration date, equipment number, calibrator, etc.

DC current sensor calibration

The calibration of DC current sensors requires different methods depending on their type and output signal (voltage, current, digital signal). The following is how to calibrate a current sensor in a DC circuit:

- 1. Confirm sensor parameters

Consult the DC sensor manual to confirm its measurement range, output signal, accuracy level, power supply voltage and other parameters. - 2. Prepare calibration equipment

Prepare the following required measurement equipment. High-precision DC current source, at least 1 level higher than the sensor. Standard multimeter/ammeter, 6½ digits or higher. Adjustable load resistor to match the output current signal. High-resolution data acquisition card or oscilloscope. - 3. Safety measures

Take safety measures to ensure that there is no risk of short circuit in the calibration circuit. Pay attention to heat dissipation when calibrating large currents.

Avoid strong magnetic field interference. - 4. Calibration process

The calibration content includes: zero calibration, full-scale calibration, linearity verification, temperature drift test, return error test, etc.

Hall Effect Current Sensor Calibration

The calibration of Hall-efektin virta-anturi requires special attention to its zero drift, linearity, temperature stability and external magnetic field interference.

- 1. Confirm sensor parameters

Consult the DC sensor manual to confirm whether it is an open-loop Hall current sensor or a closed-loop Hall current sensor. Confirm its range, output signal type, supply voltage, zero offset, etc. - 2. Calibration equipment

Prepare the following required measuring equipment. High-precision DC current source with an accuracy of ±0.05% FS or higher. Standard multimeter/ammeter, 6½-digit multimeter. A non-magnetic environment away from motors and transformers. A constant temperature box controlled at ±1℃. - 3. Safety precautions

Closed-loop Hall current sensor: Do not open the secondary compensation coil to avoid damaging the sensor.

High current calibration: Use a copper guide bar to avoid heating of the wire to affect the accuracy. - 4. Calibration process

The calibration content includes: zero calibration. Full-scale calibration (the closed-loop Hall current sensor needs to monitor the primary current and the secondary compensation current at the same time to ensure the linearity of the compensation coil.), Linearity verification. Temperature drift test. External magnetic field immunity test, etc.

Tools needed for current sensor calibration

To perform an effective current sensor calibration, you need some essential tools:

- High-precision current source: A current source that needs to be verified by a calibration test agency to generate a known reference current for comparison, with an accuracy of at least 1 level higher than the sensor.

- Multimeter or oscilloscope: 6½ digits or higher, used to measure the output of the current sensor.

- Calibrated shunt resistor: Can be used to generate a known current flowing through a resistor, especially for low current measurements.

- Test cables: For safe low resistance connections.

- Adjustment tools: These tools may include a screwdriver for manually fine-tuning a potentiometer or a digital interface for configuring the settings of modern digital sensors.

- Calibration software: If the sensor is a digital model, specialized software may be required to fine-tune settings and update firmware.

Common challenges in calibrating current sensors

- 1. Zero drift

Check if the sensor is affected by residual magnetic fields or temperature. - 2. Environmental interference

Electrical noise from nearby equipment may interfere with the calibration process. Performing the calibration in a shielded or noise-free environment helps ensure accurate results. - 3. Communication anomalies

Check the protocol configuration and wiring of digital sensors. Incorrect connections, such as loose cables or poor connectors, can cause inaccurate sensor readings. During calibration, it is important to ensure that the connections are secure and stable. - 4. Improper sensor placement

Sensor placement, especially for Hall effect sensors, is critical for accurate measurements. Improper placement can cause measurement errors. - 5. Output nonlinearity

Some sensors may exhibit nonlinearity across their entire range. This may be caused by a damaged sensor or unstable power supply. Performing a multi-point calibration across the entire range of the sensor can help obtain accurate results.

Benefits of properly calibrating current sensors

- 1. Accurate measurements

Calibrating current sensors ensures that the sensor provides accurate readings, reducing the risk of system failure or data analysis errors. - 2. Improve System Performance

Accurate current measurement helps optimize energy utilization, which improves system performance and reduces operating costs. - 3. Extend Sensor Lifetime

Regularly calibrating current sensors can help detect any performance issues early, extend the life of the sensor and ensure long-term reliability. - 4. Comply with standards

Many industries have strict requirements for measurement accuracy. Proper calibration ensures compliance with these standards, which is especially important in regulated industries such as healthcare, automotive, and aerospace. - 5. Enhance Reliability

Well-calibrated sensors ensure more reliable readings, resulting in fewer failures and more informed decisions in critical applications.

Following the steps to calibrate current sensors and using the right tools can ensure that the sensor provides accurate readings throughout its service life. Regularly calibrating current sensors, whether it is DC current sensor calibration or Hall effect current sensor calibration, will ensure that your system runs smoothly and efficiently.

Tietoja Hangzhi

Shenzhen Hangzhi Precision Electronics Co., Ltd. on teknologisesti johtava yritys, joka on omistautunut huipputarkkojen virta-antureiden, jänniteantureiden ja huipputarkkojen sähköisten mittauslaitteiden tutkimukseen ja kehittämiseen, tuotantoon, myyntiin ja ratkaisujen räätälöintiin. Pyrimme rakentamaan tunnetun tuotemerkin . Tarkkuusvirta-antureita ja tarkkuuselektronisia mittauslaitteita tasavirta-alalla ja pyrkii kehittymään kansainvälisesti johtavaksi tarkkuuselektroniikan johtajaksi tasavirtajärjestelmien alalla.