Applications of high-precision current sensors in semiconductor equipment manufacturers

Application solutions of high-precision current sensors in semiconductor equipment manufacturers

Industry Background

For manufacturers of core semiconductor equipment such as etching, thin film deposition, ion implantation, and chemical mechanical polishing (CMP), the core competitiveness of their equipment lies not only in functional implementation but also in three key dimensions: first, the long-term stability of the process; second, high consistency among equipment of the same model; and third, the ability of key parameters to resist drift after long-term operation.

The achievement of these dimensions relies heavily on the accurate acquisition of real current data in key power supply and load circuits—current data is the foundation for closed-loop control and process stability assurance, and high-precision current sensors are the core components for achieving this foundation.

Typical Application Segments

1. Application Segment 1: Precise Monitoring of Critical Current Circuits in Equipment

Core Application Locations

- High-power DC power supply output terminal

- Radio frequency (RF) power supply front-end DC bus

- Heater, electromagnetic coil, and motor drive circuits

Application Implementation Method

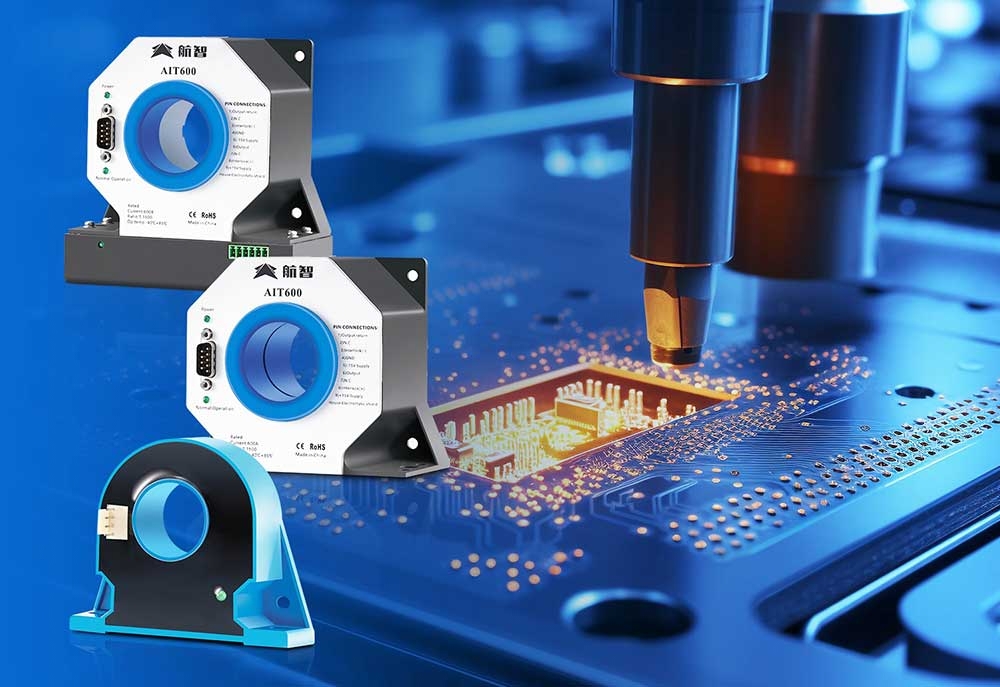

Hangzhi fluxgate high-precision current sensors are directly connected in series with the critical current circuits of the equipment, providing low-drift, high-consistency real-time current feedback signals to the equipment’s programmable logic controller (PLC) or main control board. Their core functions cover three main scenarios: first, closed-loop control of the process; second, real-time monitoring of equipment operating status; and third, rapid identification and early warning of abnormal currents.

2. Application Stage Two: Equipment Consistency Calibration and Factory Calibration

During the three key stages of equipment factory testing, overall machine debugging, and on-site installation and calibration, Hangzhi high-precision current sensors can serve as metrology-grade reference devices, undertaking three core tasks: first, calibrating the accuracy deviation of the internal current detection channel of the equipment; second, correcting measurement consistency deviations between different batches of equipment; and third, ensuring the consistency and reproducibility of process parameters for equipment of the same model.

Core Advantages of the Solution

This solution utilizes Hangzhi’s core fluxgate closed-loop technology, possessing four core advantages: First, high measurement accuracy, meeting the precision control requirements of semiconductor equipment; second, low zero-point drift and low temperature drift, ensuring long-term operational stability; third, strong anti-interference capability, adapting to the complex electromagnetic environment of semiconductor equipment; and fourth, excellent stability, enabling long-term reliable operation.

Through these advantages, equipment manufacturers can directly enhance two core values: first, significantly strengthening equipment process stability; and second, improving the market reliability of branded products.

Core Application Value

Hangzhi’s high-precision current sensor, as a core fundamental component, provides crucial support for the high-end upgrade, precision control, stable operation, and consistency assurance of semiconductor equipment, making it an important supporting device for equipment manufacturers to enhance their core competitiveness.

Μάθε περισσότερα για high precision current sensors

Σχετικά με το Hangzhi

Shenzhen Hangzhi Precision Electronics Co., Ltd. είναι μια τεχνολογικά κορυφαία επιχείρηση αφιερωμένη στην έρευνα και την ανάπτυξη, την παραγωγή, τις πωλήσεις και την προσαρμογή λύσεων για αισθητήρες ρεύματος υψηλής ακρίβειας, αισθητήρες τάσης και ηλεκτρικά όργανα μέτρησης υψηλής ακρίβειας. Επιδιώκουμε να δημιουργήσουμε μια γνωστή μάρκα fluxgate αισθητήρες ρεύματος ακριβείας και ηλεκτρικά όργανα μέτρησης ακριβείας στον τομέα του συνεχούς ρεύματος, και προσπαθούμε να εξελιχθούμε σε έναν διεθνώς κορυφαίο ηγέτη στον τομέα των ηλεκτρονικών ακριβείας στον τομέα των συστημάτων συνεχούς ρεύματος.